CHEMICAL INDUSTRY:

Industrial filtration is crucial for the chemical sector, as it helps to guarantee the quality and purity of end products. The filtration process is used to remove unwanted solid particles from chemical products, ensuring that they meet quality standards and are safe to use.

How can hermetic candle filters (HBT) help the chemical industry?

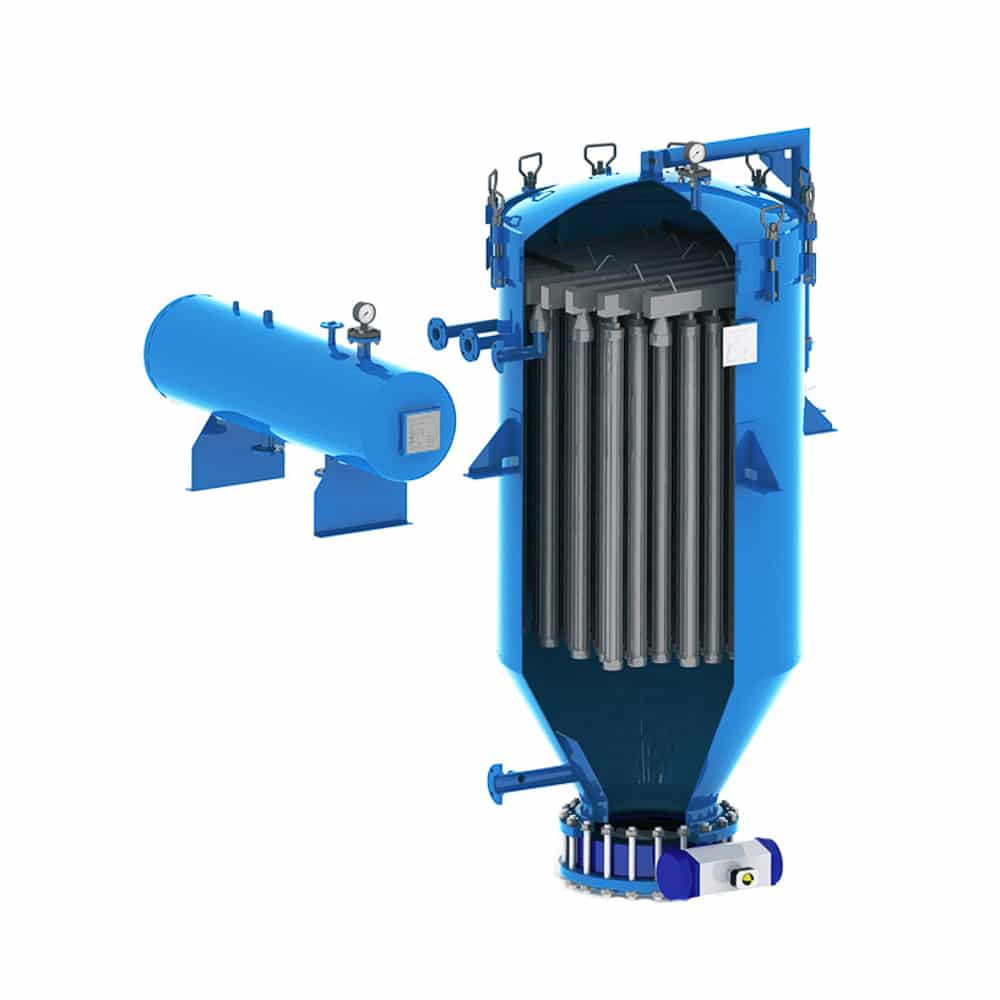

Hermetic candle filters are extremely useful for the chemical industry. These filters are highly efficient at separating liquids from solids and can operate under a wide range of pressure and temperature conditions. In addition, the hermetic nature of these filters allows for adequate control over the process environment, minimizing the risk of cross-contamination and increasing operational safety.

Our Filters:

How do Hollbras HBT vertical candle filters work?

HBT candle filters perform solid-liquid separation, a crucial process in the chemical industry. The filtration process begins with the formation of a pre-coat, either with the solid to be filtered or with a filtration aid. Once the pre-coat is formed, the liquid to be filtered is pumped into the filter, where the internal pressure pushes it through the filtration candles. The solid particles are retained on the surface of the candles lined with the filter fabrics. The filtration process is terminated when the filter reaches its solid limit. The retained solids can be discharged dry, by drying the solids and cleaning the filtration candles by blowing inert gas air against the flow; or wet, by washing the filter elements also against the flow using water or solvents suitable for the process. This filtration process can be completely automated.

SPARE PARTS

What are the applications of HBT filters in the chemical industry?

What are the benefits of Hollbras candle filters (HBT) for the chemical industry?

The benefits of candle filters in the chemical industry are vast. These benefits include high filtration efficiency, the possibility of continuous or batch operation, and low maintenance costs.

- Efficiency and quality:

The capability of leaf filters to efficiently retain solid particles guarantees the quality of the end product and a reduction in process losses.

- Versatility:

Leaf filters can be used with different types of filters, allowing them to be adapted to the specific needs of each application.

- Ease of operation and maintenance:

Leaf filters are simple to operate and have low maintenance costs. In addition, filter cleaning is quick and easy, minimizing equipment downtime.

Can Hollbras filters help with environmental and sustainability issues?

The adoption of candle filters in the chemical sector can contribute to the sustainability of the production process. In addition to optimizing the consumption of resources such as water and energy, the use of tube filters promotes the recovery of byproducts that can be reused or recycled, reducing waste generation.

Future filtration challenges in the chemical sector:

The chemical industry faces many challenges in the filtration field. One of the biggest challenges is the growing demand for more efficient and sustainable filtration solutions that minimize energy consumption and waste production. Finally, operational safety remains a primary concern, requiring the development of increasingly secure and reliable filters. Through the supply and maintenance of filtration equipment and operator training, Hollbras is here to help our customers overcome these challenges.